A new produce sanitation process combines hydrogen-peroxide fog with UV light to eliminate contamination and extend shelf life.

Ninth-generation farmer Paul Moyer is looking at produce sanitation in a whole new light. By combining ultraviolet rays and a hydrogen-peroxide vapor, he, in partnership with Dr. Keith Warriner, a food scientist at the University of Guelph in Ontario, have created a process that they say kills 99.9% of mold, mildew and pathogens.

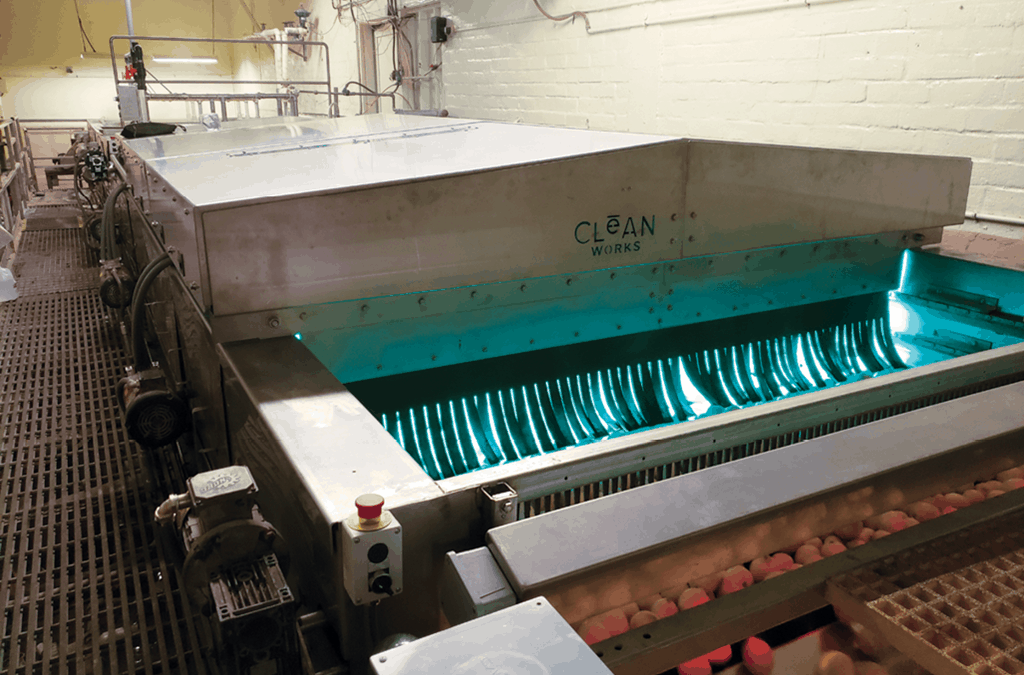

Clean Works, which is based in the Niagara region of southern Ontario, recently won the International Association for Food Protection’s Food Safety Innovation Award for the Clean Vertification sanitation process.

Moyer, co-owner of Clean Works, encountered issues with sanitation when his farm entered the candy-apple business. In 2015, the industry encountered a listeria outbreak that killed seven people and hospitalized 34. “We weren’t implicated, but it certainly affected us,” Moyer says. “And then I said, ‘Huh. There should really be something that cleans produce better.’”

Since chocolate and caramel don’t mix well with water, Moyer started looking into creating a new way to clean produce. “I’ve always thought that water acts [as] more of a vector for pathogens than it does [as] a solution for pathogens,” he says. “Whatever’s in the water spreads to the other fruit, so if there’s one infected fruit, it’ll spread to the other fruit or vegetables.”

After experimenting with a few different options and working closely with Warriner, he found a process that not only sanitizes produce, but increases shelf life by 25%.

“We doubled the efficacy of just the hydrogen peroxide and UV light. So, it’s a very, very effective way of killing both pathogens, mold and mildew. So, essentially, the hydrogen and the oxygen radicals are very powerful in this chamber. And then that chamber, will break down pathogens from E. coli, salmonella and listeria, as well as mold and mildew that a lot of people refer to as a rot.”

Produce Grower: What need are you hoping to fill with this new technology?

Paul Moyer: I wanted to have something that didn’t use water. There are a lot of fruits and vegetables that don’t like water. Apples aren’t a problem, but then you get into peppers or tomatoes or blackberries or raspberries … you can imagine, you just can’t really put them through water very well. So I wanted to create something that was totally, totally different — a different way of thinking about how we clean things.

So, I was thinking totally differently and I took it a totally different way.

PG: How does the whole process work?

PM: So, essentially, it all works together. That’s kind of the magic of it. When you mix the UV light with the hydrogen peroxide with the ozone gas, you’re creating an atmosphere around that piece of fruit. So, it doesn’t have to be underneath the light for it to be effective. It would be like you walking into a room but you’ve got a whole bunch of things going on. And the mixture of the gases and so on is what is affecting the mold and the mildew and the pathogens and the viruses on that piece of fruit. And because they’re microscopic, this is all chemistry that’s happening on a microscopic level. It’s not going to hurt the fruit because it’s a fairly large piece of organic matter. But when you start talking about viruses and mold and mildew spores, they’re teeny tiny and it’s very, very powerful. And that’s why it doesn’t affect the fruit in a bad way, but it certainly affects the pathogens and the mold and mildew and the viruses.

PG: What sorts of produce would this system be effective on? Would it include greenhouse crops like tomatoes, cucumbers and microgreens?

PM: We’re getting a 3.49 log on microgreens, so it works on lettuces and it works on all sorts of fruits and vegetables with different results but certainly surpassing the traditional results of water by 1,000-fold. So, 1 log is a 90% kill and 2 logs is a 99% kill. Three logs is a 99.9% kill. So far, far, far more effective. When you get a 1 log reduction you think, “Hey, that’s pretty good.” Traditional wash methods — if you put it underneath the sink and washed it and rubbed it a little bit, you’d get a 0.5 log fill.

PG: What sort of testing process has this gone through and how have you verified the efficacy?

PM: Not only has it been accepted by the scientific community because we’ve had a number of papers that have been published in the industry, but we won the International Association for Food Protection’s Food Safety Innovation Award and we beat out Monsanto and 3M and all the big players, so that was a pretty big deal.

PG: How can this technology be used in the greenhouse industry?

PM: As the industry changes and so on, everybody is being affected by food safety. So, the more intervention steps or hurdles you put into that process, the safer the consumer deems the product to be. There have been issues in the past. And nobody wants to have an issue. This is an intervention step. A lot of people are saying. “We’re fine. We’ve never had a problem.” The problem is the science is changing very quickly. At the turn of the century, everybody was very concerned about dairy products and then it was meat products and now it’s coming to the produce world. And not only is it helping with the food safety aspect, but it’s increasing the shelf life.

PG: How does the technology help monitor and document results?

PM: Sooner or later, people are going to say, “You put this intervention step in and that’s really great. But when did you do it? When did this occur, and did it hit the parameters that it’s supposed to hit?” So, we can monitor the ozone and when we did it and so on. When we ship caramel apples into the U.S., you know, some of our customers are saying, “We’d like to see the fact that you put your product through these processes.”

Read original interview here: https://www.producegrower.com/article/food-safety-fresh-and-clean/